Sheroz Earthworks - An Overview

Sheroz Earthworks - An Overview

Blog Article

Some Of Sheroz Earthworks

Table of ContentsThe 2-Minute Rule for Sheroz EarthworksSheroz Earthworks - QuestionsThe Single Strategy To Use For Sheroz EarthworksSheroz Earthworks Things To Know Before You BuyWhat Does Sheroz Earthworks Do?

For any type of earthwork service provider, it is vital to do work with quality, precision, and on routine. Making use of maker control in job equipments enables maximizing the different phases in the earthwork procedure, from intending to the upkeep stage - trimble gps. The device control system assists the device operator in attaining the target plane rapidly and quickly

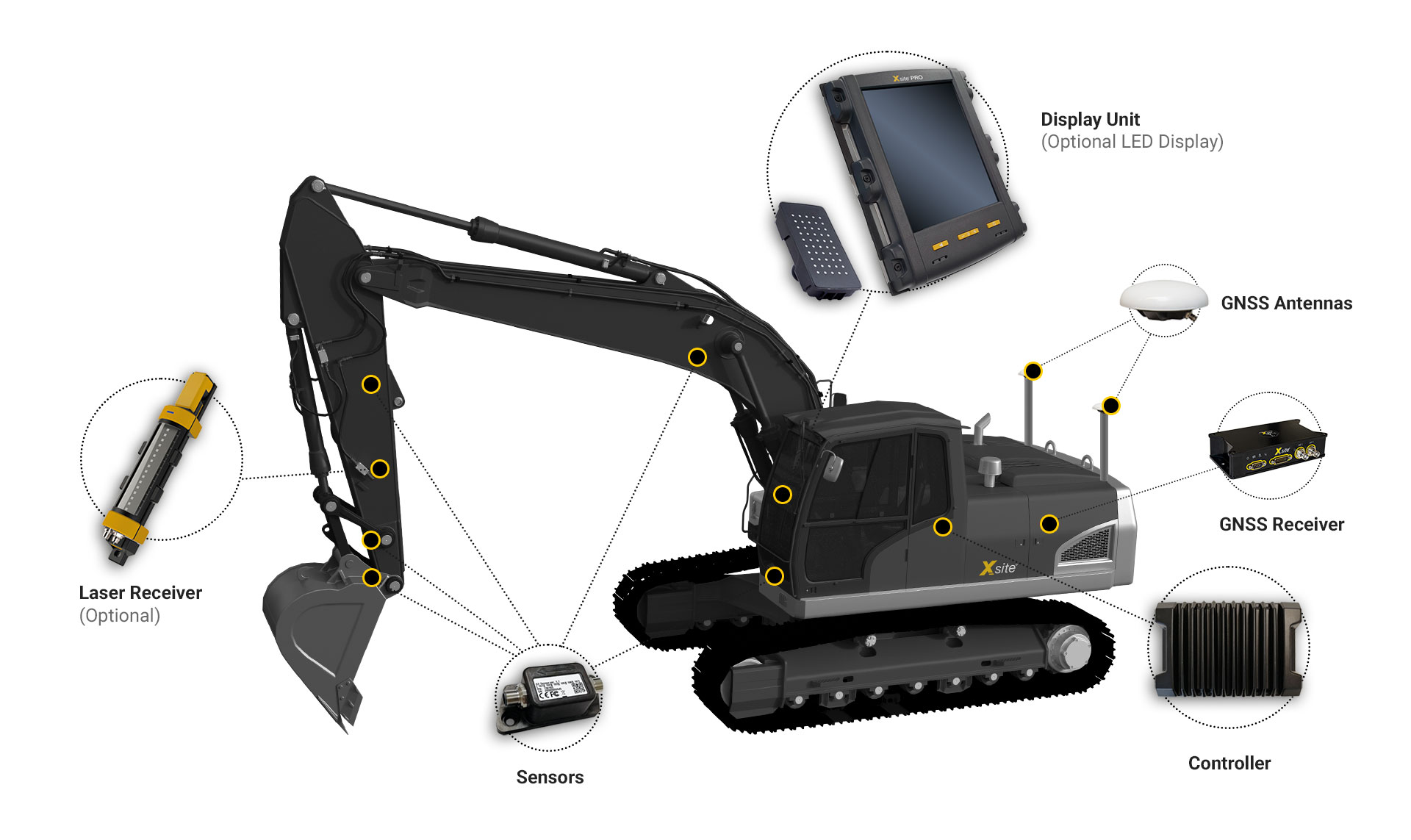

The equipment control system overviews the operator with centimeter accuracy. With Xsite PRO 3D, you'll constantly recognize precisely how much to cut or fill. Your regional Xsite technical support can guide you and assist with any kind of problems without checking out the site. Remote support saves time and money, as it reduces downtime in jobsites.

Some Of Sheroz Earthworks

Our system's elements are carefully developed to endure the harsh conditions of building sites. Contrast of the same task implemented utilizing equipment control versus the typical technique discloses that, on standard, the traditional approach calls for 50% more time to achieve the very same job as the technology-assisted technique.

Enter the Xsite machine control system; it's right here to give you with a significant advantage when functioning with earthmoving machinery. Discover exactly how Xsite Device Control can enhance your efficiency and make sure work safety and security! Xsite Machine Control systems can be mounted to any kind of excavator from mini excavators to large mining excavators.

Just how does maker control work? In 2D systems, the equipment is geared up with adjusted disposition sensing units. These sensing units are placed on the pre-determined components of the maker in excavators the sensor are normally installed to the frame, boom (or booms), miner arm and to the fast coupler - fj dynamics auto steer price. By utilizing the information obtained from these sensors the system can compute the exact position of the excavators pail idea in significance to a reference factor.

The system is extremely easy to discover the essentials can be educated in under one hour of training. Exactly how does the remote assistance work? A cordless net link makes it feasible to develop a remote connection between the device control system and the solution.

6 Simple Techniques For Sheroz Earthworks

Xsite Maker Control systems support open typical documents styles, making it possible for seamless details flow from one system to one more. Depending on your selection of system (with or without placing, i.e., 2D or 3D), your machine is geared up with inclination sensing units, a controller system, and a display/operating panel.

Many software and hardware solutions exist to help determine an equipment's existing setting on the planet and contrast it with a wanted style surfaceand construction drivers can do more to leverage the advantages. Maker control is using different positioning sensing units and a screen to supply the operator with a reference in between the placement of the pail or blade and the target grade.

Relying on the setup, device control systems can offer the driver with an easy visual overview to bucket or blade placement, or can automatically relocate the blade to grade by speaking to the machine's hydraulics - https://pagespeed.web.dev/analysis/https-sheroz-com-au/hhalrkoyid?form_factor=mobile. There are device control systems available for practically any maker: graders, dozers, excavators, soil and asphalt compactors, scrapers, trimmers, grating equipments, and pavers

Little Known Questions About Sheroz Earthworks.

Some advantages include reduced rework, improved task performance, and reduced checking costs. Device control can also help increase productivity and lower general expenses. This modern technology is altering the means the building and construction market functions. Building and construction devices without equipment control will click over here now end up being a distant memory and the benefits got from it will be numerous.

Trimble equipment control systems give a myriad of advantages to anybody that utilizes earthwork machinery and, at EarthCalc, we can give you with 3D data for your equipment control-enable equipment. Unsure if device control is worth the cost? Consider the following reasons that you require to consider this alternative.

Utilizing GPS aligned with your 3D design files, these systems practically ensure that you will certainly eliminate or place the appropriate quantity of material at the building site. On many building sites, rework is an usual and aggravating reality, yet with Trimble maker control, you can eliminate the need for rework.

7 Easy Facts About Sheroz Earthworks Explained

Typically, with Trimble maker control, you can eliminate excess equipment at a certain task website. For instance, a task that might have required the usage of 3 or four items of excavating devices currently may need only two tools to complete the same task in much less time. This allows you to move your devices to an additional task website and deal with several work at once.

Report this page